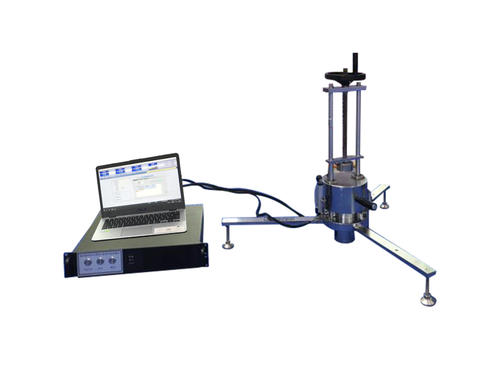

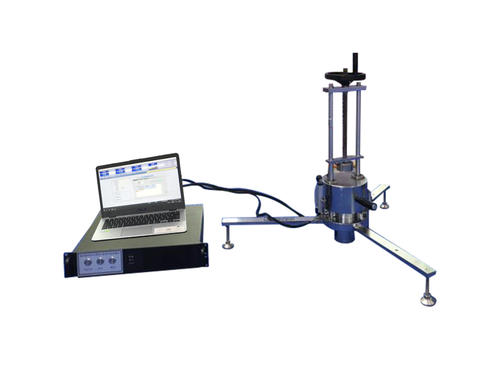

ZY-8736 Plastic Track Vertical Deformation and Impact Performance Tester

★Design standard of vertical deformation detector for plastic track:

The structure of the product meets the requirements of the IAAF and European standards EN14808-2003 "Measurement Method for Impact Absorption of Sports Ground Ground Layer" and EN14809-2003 "Measurement Method for Vertical Deformation of Sports Ground Ground Layer" for test equipment.

★The main content of the vertical deformation detector of the plastic track:

This product is mainly used to determine the impact absorption performance of plastic sports fields. The machine weight simulates the effect of the human body and impacts the synthetic surface layer, and the test results are calculated by the computer system. The design requires the instrument structure to be simple and dexterous, and to provide reliable testing equipment for the testing of plastic synthetic ground in stadiums.

★The main structure of the vertical deformation detector of the plastic track

(1) Cabinet

(2) Mobile system

(3) Hammer body

(4) Lifting system, release system

(5) Gravity buffer system

(6) Force measuring system sensor

(7) Letter collection system

(8) Computer and other components

★Hammer lifting and release device

This machine has a rectangular structure with a weight of 20kg. The lifting method adopts manual hammer lifting, foot lifting hammer, and foot lifting hammer device, which solves the problem of heavy hand-held weight and unstable lifting. The electric hammer needs power supply and the instrument is large in size. And other issues; the use of this structure is convenient, practical, and low-cost.

★Test method of shock absorption tester

Place a force plate with a spherical chassis on the surface to be measured, and make a weight of 20 Kg fall freely onto an anvil. The anvil transmits the force to the force plate through the spring and impacts the side surface of the ground. The force sensor installed on the force plate records the large value of the impact return force. This force value is compared with the force value measured by the mechanism on a hard surface (such as a concrete floor), and the percentage of the impact return force of the composite surface is calculated as the impact absorption value of the composite surface:

Impact absorption value=(1-Fs/Fc)*100%

Where: Fs-the return value of the impact on the synthetic surface

FC-the return value of the impact on the concrete surface

In order to obtain credible data, the average value of 3 calculations is taken as the impact absorption value of the surface layer.

★Technical Index of Impact Absorption Tester

A. Heavy objects, weight 20 Kg ± 0.1Kg, with a hard impact needle, the diameter of the needle is generally not less than 20mm.

B. Anvil, the surface hardness is not less than HRC 60.

C. Spring, the elastic range is 1750~2250N/mm, if the elastic range exceeds the standard, the measured result should be added with the correction coefficient.

D. Guide post, the frictional resistance between the heavy object and the guide post is less than the quality requirement of the heavy object, and can meet the guiding requirement.

E. Force plate with a diameter of 70 mm and a spherical radius of 500 mm at the bottom. The small distance between the center of the force plate and the supporting foot of the machine should not be less than 200mm.

F. The distance between the bottom of the impact needle and the anvil (the drop height of the weight), 55mm±0.25mm.

G. Force measuring mechanism, the accuracy is not more than 0.5%, and the conversion speed is not more than 0.3 milliseconds.

★Test method of vertical deformation tester

Place a force plate with a spherical chassis on the surface to be measured, and make a weight of 20 Kg fall freely onto an anvil. The anvil transmits the force to the force plate through the spring and impacts the side surface of the ground. The force sensor installed on the force plate records the large value of the impact return force. At the same time, the amount of surface deformation at this time can be recorded. Place a heavy object at a certain height above the anvil so that the impact force is 1500N±100N, test 4 times continuously within one minute and record the amount of deformation.

The average value of the subsequent three deformation results is the vertical deformation value of the surface.

★Technical indicators of vertical deformation tester

A. Heavy objects, weight 20 Kg ± 0.1Kg, with a hard impact needle, the diameter of the needle is generally not less than 20mm.

B. Anvil, the surface hardness is not less than HRC 60.

C. Spring, the elastic range is 300~400N/mm, if the elastic range exceeds the standard, the measured result should add the correction coefficient.

D. Guide column, the frictional resistance between the heavy object and the guide column is less than the quality requirement of the heavy object, and can meet the guiding requirement.

E. Force plate with a diameter of 70 mm and a spherical radius of 500 mm at the bottom. The small distance between the center of the force plate and the supporting foot of the machine should not be less than 200mm.

F. The distance between the bottom of the impact needle and the anvil (weight drop height) can be adjusted to 1mm.

G. Force measuring mechanism, the accuracy is not less than 0.5%, and the conversion speed is not more than 0.3 milliseconds.

H. Deformation measurement mechanism, the accuracy is not less than 0.01mm, and the conversion speed is not more than 0.3 milliseconds.

★Using environment of impact absorption tester

Power supply: 220V ±10%, 50Hz

Data processing capacity: up to 333kHz

Maximum impact resistance value: 1.5T

Fine adjustment range: 40 mm

Spring elasticity: 2000N/mm

Weight of heavy hammer: 20kg

Impact contact surface hardness: HRC50

Force plate: diameter 70 mm; top spherical radius 500mm

★Using environment of vertical deformation meter

Power supply: 220V ±10%, 50Hz

Data processing capacity: up to 333kHz

Fine adjustment range: 40 mm

Maximum impact resistance value: 1.5T

Impact resolution: 0.01N

Limit deformation measurement range: 3 mm

Deformation resolution: 0.001 mm

Spring elasticity: 30N/mm

Weight of heavy hammer: 20kg

Impact contact surface hardness: HRC50

Force plate: diameter 70 mm; top spherical radius 500mm